The New Energy Vehicle Tire Revolution: How Granular Precipitated Silica Achieves 15% Energy Efficiency Breakthrough

With global new energy vehicle (NEV) adoption surpassing 20% (2023 data), tire manufacturers are demanding unprecedented energy-saving performance from materials. Recently, a novel granular precipitated silica product has demonstrated remarkable results in tire tests for leading automakers like Tesla and BYD—reducing rolling resistance by 18% and extending driving range by 15%.

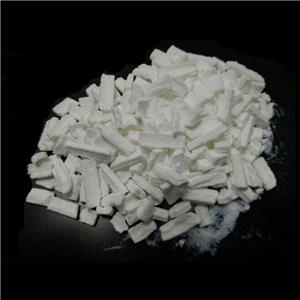

Structural Advantages of Granular Form

Compared to conventional powdered silica, the 50-100μm granular precipitated silica exhibits three breakthrough characteristics:

1. Oriented Network Structure: Ordered silica dispersion within granules enhances tread rigidity.

2. Surface Activation Technology: Modified treatment improves silica-rubber interfacial bonding by 40%.

3. Humidity Regulation: Microporous structures between granules dynamically adjust moisture permeability.

Game-Changing Production Process

Our third-generation precipitated silica manufacturing technology employs gradient precipitation to achieve:

Phase 1: Nano-scale silica core formation (<20nm)

Phase 2: Controlled aggregation into porous granules

Phase 3: Targeted silane coupling agent coating

This process ensures a stable specific surface area of 180-200m²/g for granular products, far exceeding traditional powdered silica (120-150m²/g), making it an ideal new energy vehicle material solution.

Industry Impact: If 50% of global NEVs adopt this technology, annual battery savings could equate to 250,000 tons of lithium carbonate—accelerating sustainable mobility.